-

Accurate and Efficient | A&E Carbon Fiber PrepregLaser Marking Process Enhances Process Efficiency

Release time:2024-08-21 News section:Company News

-

In the field of carbon fiber materials, A&E has alwaysbeen trusted by global customers with excellent manufacturing processes and relentless innovation spirit.

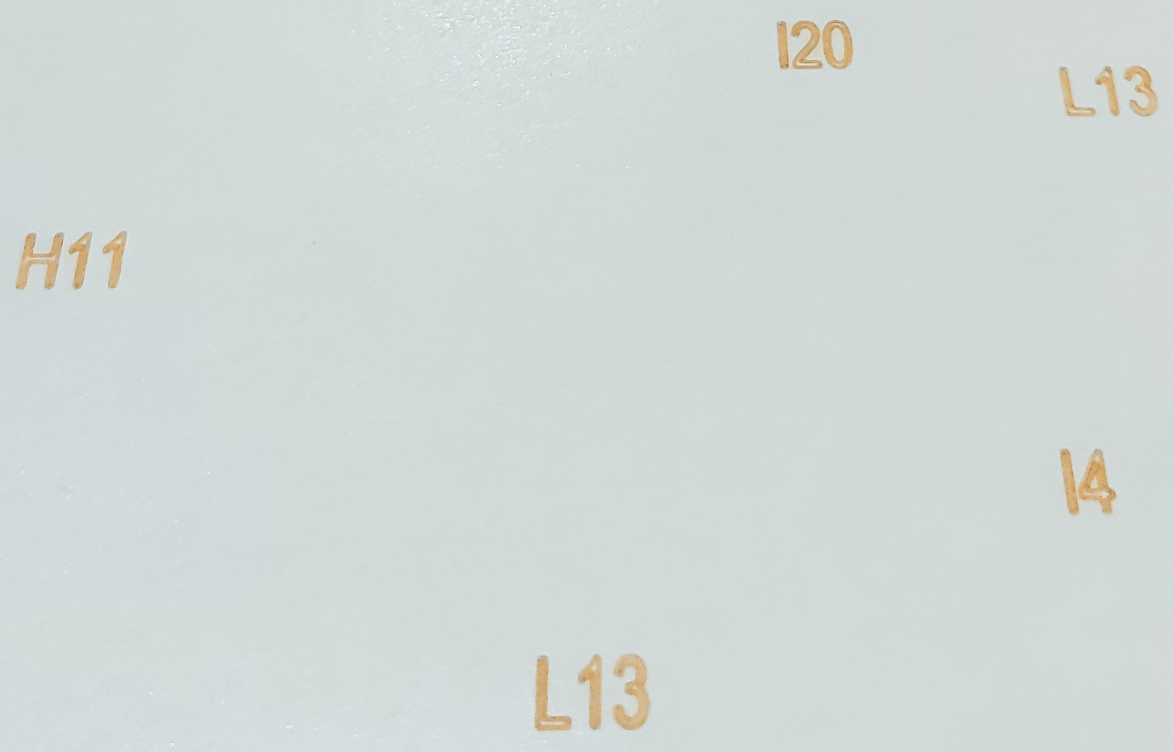

As a leading international manufacturer of carbon fiber baseball batsand carbon fiber bicycle racks, A&E requires preimpregnated materials to meet the needs of different sizes,styles,andusage parts in the product manufacturing process, and the quantityused is numerous.Therefore, before cutting the pre impregnatedmaterials, it is necessary to first label them with numbers or codes, sothat downstream processes can personalize the cutting according tospecific labeling.

In the past, the labeling of prepreg sheets required manual annotation,which was labor-intensive and inefficient. After A&E used 2D laser marking technology as the identification mark for cuttingmaterials, it not only reduced the workload of workers, improved accuracy, and reduced waste, but also greatly improved work efficiency.

The advantages of 2D laser marking process

Laser marking is a process in which a high-energy continuous laserbeam is generated by a laser generator, and the focused laser is applied to the printing material, causing the surface material to instantlymelt or even vaporize.By controlling the path of the laser on the material surface, the desired graphic or digital markings are formed.

After using 2D laser marking process,A&E has become an ideal choice for sheet identification due to its high precisionand speed.Under the precise control of the laser, each pre impregnatedsheet can be instantly assigned a unique identifier, which is clear, durable, and not easily worn or faded even in complex productionenvironments.This not only greatly reduces the workload of workers,but more importantly, it ensures that every piece of material can beaccurately identified and used, thereby reducing waste and improvingproduct quality.

Significant improvement in process efficiency

Before the A&E carbon fiber prepreg is officially used inspecific products, it needs to go through processes such as yarn blending, cutting, and batching.The 2D laser marking process occursafter yarn blending and before cutting.

lt is precisely with the efficient 2D laser marking process that theprocess efficiency of prepreg is greatly improved, allowing seamlessconnection of cutting, batching and other processes, faster pace, andfully automated operation throughout the process, improving operationalaccuracy while reducing labor costs.

As another innovative measure of A&E in the prepregprocess, the 2D laser marking process not only reflects the advantagesof the enterprise in production and technology, but also directly reflectsthe strength of the enterprise. ln the field of research and production ofcarbon fiber materials,Zhongshan Rongnan has always adhered totechnological innovation as the driving force, continuously improvingproduct performance and quality.In the future, we will continue to uphold the spirit of innovation,constantly explore and introduce more advanced technologies andprocesses, and bring more high-quality carbon fiber products and betteruser experience to global users.

-

Related

information

-

-

Exquisite and unparalleled |Application of innovative cutting technology for A&E carbon fiber prepreg

The application of 2D cutting technology has achieved significantresults in the production of A&E carbon fiber bicycleframes.

-

lmproving quality and efficiency | A&E's CNC yarncutting (2D plotter) technology leads a double leap in quality andefficiency

A&E has transformed its pre impregnated cuttingprocess to ensure product quality and significantly reduce productioncosts.

-

Building Defense through Performance | A&E Safety Emergency Drill Successfully Held in the First Half of the Year

A&E held an emergency safety drill for the first half of 2024

-

Quality • Casting the cornerstone|Take you into the Rongsui branch of A&E

About A&E Machinery Industry Co.,Ltd.Rongrui Branch

-