-

lmproving quality and efficiency | A&E's CNC yarncutting (2D plotter) technology leads a double leap in quality andefficiency

Release time:2024-08-21 News section:Company News

-

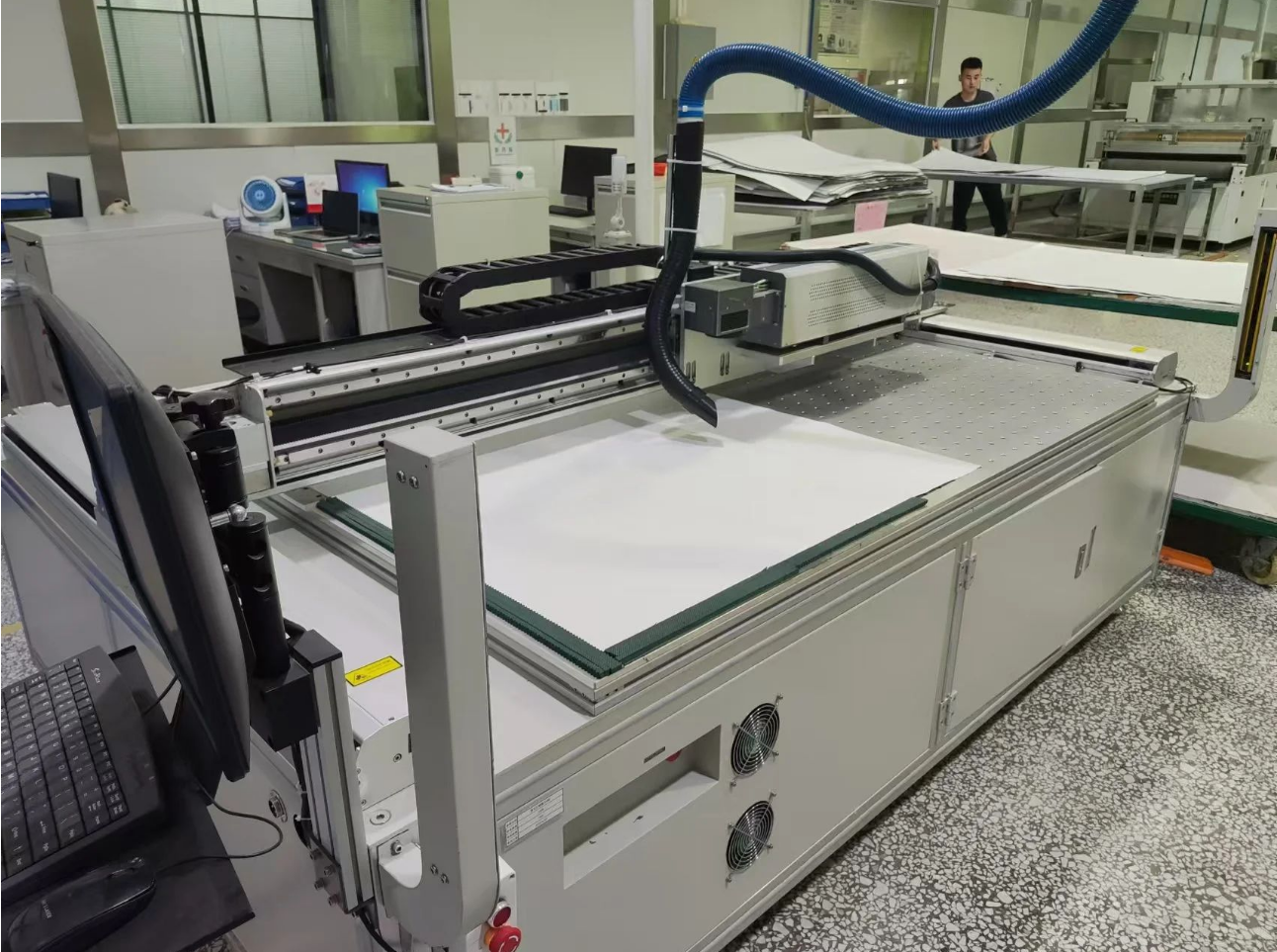

As a large intelligent manufacturing enterprise in the field of carbon fiberprepreg and carbon fiber products, A&E has alwaysbeen committed to technological innovation and process improvement.Against the backdrop of increasing global manufacturing attention tocarbon fiber composite materials,A&E has fully adopted leading CNC yarn cutting (2D plotter) equipment in the cuttingprocess of carbon fiber prepreg.Through this process change, we notonly ensure product quality, but also significantly reduce production costs, marking another major leap in the company's production process.

CNC yarn cutting equipment leads to furtherimprovement of production efficiency

The comprehensive use of CNC yarn cutting (2D plotter) equipment isan important milestone in the production process of A&E.

Traditional die stamping equipment requires frequent replacement ofthe die during the cutting process, which consumes a certain amount oftime and manpower.The problem of insufficient accuracy also makesdie stamping equipment prone to material waste during the cuttingprocess.

(Traditional knife molds)

(Traditional knife die stamping equipment)

The CNC yarn cutting (2D plotter ) equipment is completely controlled bya computer, and the prepreg is tightly adhered to the worktable throughvacuum adsorption.The partitioned suction makes small sample cuttingsimple and efficient.In addition, CNC yarn cutting (2D plotter) can accurately control the thickness and path of the cutting blade, achievinghigh-precision cutting of complex shapes, greatly improving productionaccuracy and efficiency.

International quality: details determine successor failure

International quality: details determine successor failureln the field of carbon fiber manufacturing, production details often determine product quality.At present, A&E can achieveneat cutting and precise size of each batch of carbon fiber prepreg inthe manufacturing process,providing convenience for subsequentprocessing and improving product uniformity and standardization.Thisultimate pursuit of quality has earned ZA&E's carbonfiber products a high reputation in the international market and becomea common choice in many high-end application fields.And this is alsothanks to the achievements of our intelligent yarn cutting process.

Cost savings: economic benefits in productionprocess innovation

ln addition to improving product quality, the application of CNC yarncutting (2D plotter) equipment has also brought significant cost savings.The CNC yarn cutting (2D plotter) equipment can quickly adapt to thecutting needs of different pre impregnated materials through an automated control system, greatly reducing the time required forequipment adjustment.In addition, high-precision cutting also meansless material loss, further reducing production costs.

In fact, the production technology innovation of A&E is not only reflected in advanced production equipment, but also in ouryear after year technological innovation and research and developmentinvestment.In the future, we will continue to uphold the spirit of innovation, continuously optimize production processes, and improvemanufacturing processes to meet increasingly stringent marketdemands.At the same time, we will actively explore new applicationareas and provide more high-quality carbon fiber products to globalcustomers.

-

Related

information

-

-

Accurate and Efficient | A&E Carbon Fiber PrepregLaser Marking Process Enhances Process Efficiency

As another innovative measure of A&E in the carbon fiber prepreg process, the 2D laser marking process not only reflects the company's advantages in production and technology, but also directly enhances the company's strength.

-

Exquisite and unparalleled |Application of innovative cutting technology for A&E carbon fiber prepreg

The application of 2D cutting technology has achieved significantresults in the production of A&E carbon fiber bicycleframes.

-

Building Defense through Performance | A&E Safety Emergency Drill Successfully Held in the First Half of the Year

A&E held an emergency safety drill for the first half of 2024

-

Quality • Casting the cornerstone|Take you into the Rongsui branch of A&E

About A&E Machinery Industry Co.,Ltd.Rongrui Branch

-