-

Exquisite and unparalleled |Application of innovative cutting technology for A&E carbon fiber prepreg

Release time:2024-08-21 News section:Company News

-

ln the field of carbon fiber materials, A&E has beenhighly praised by global customers for its excellent craftsmanship andinnovation capabilities.

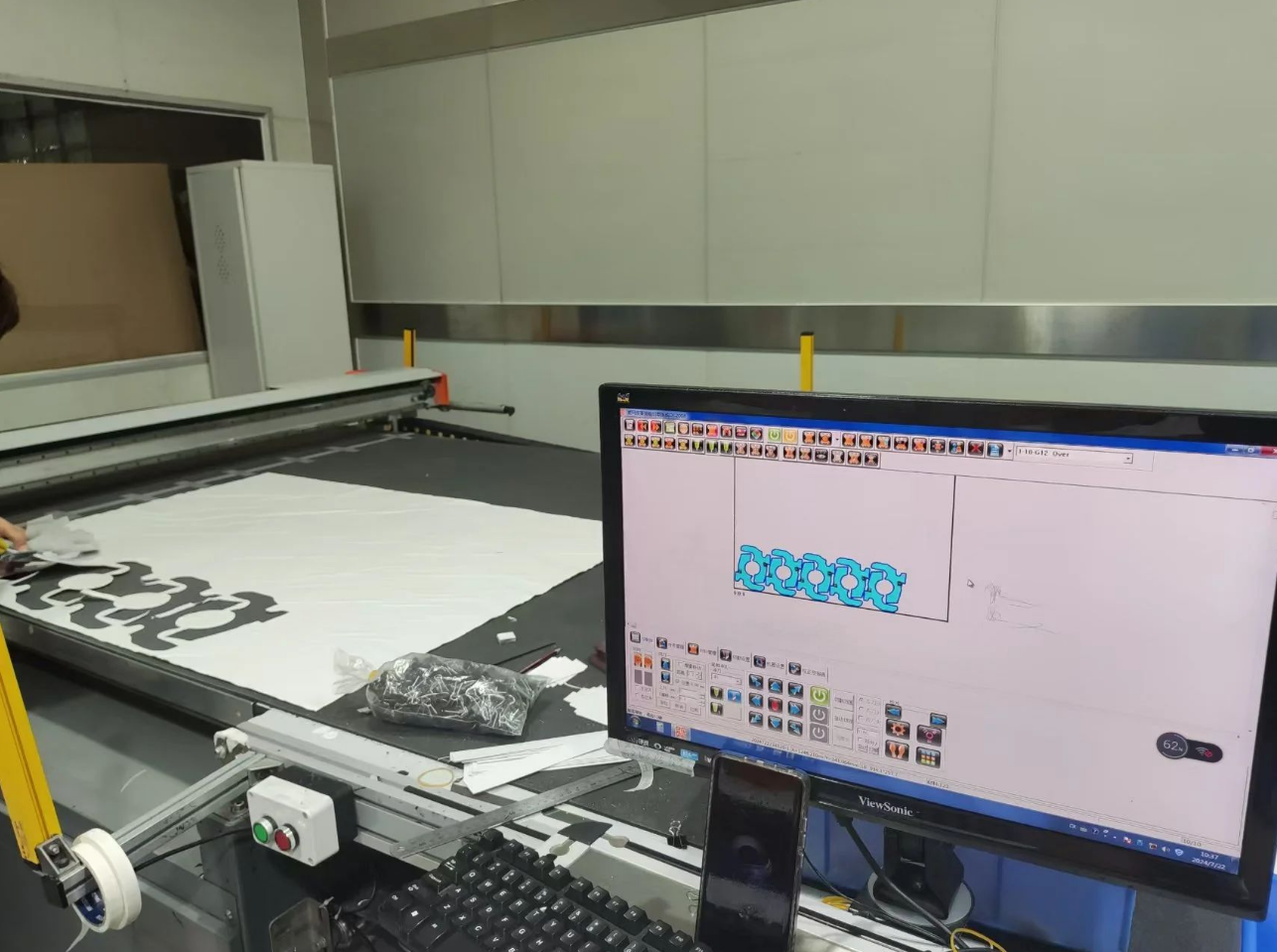

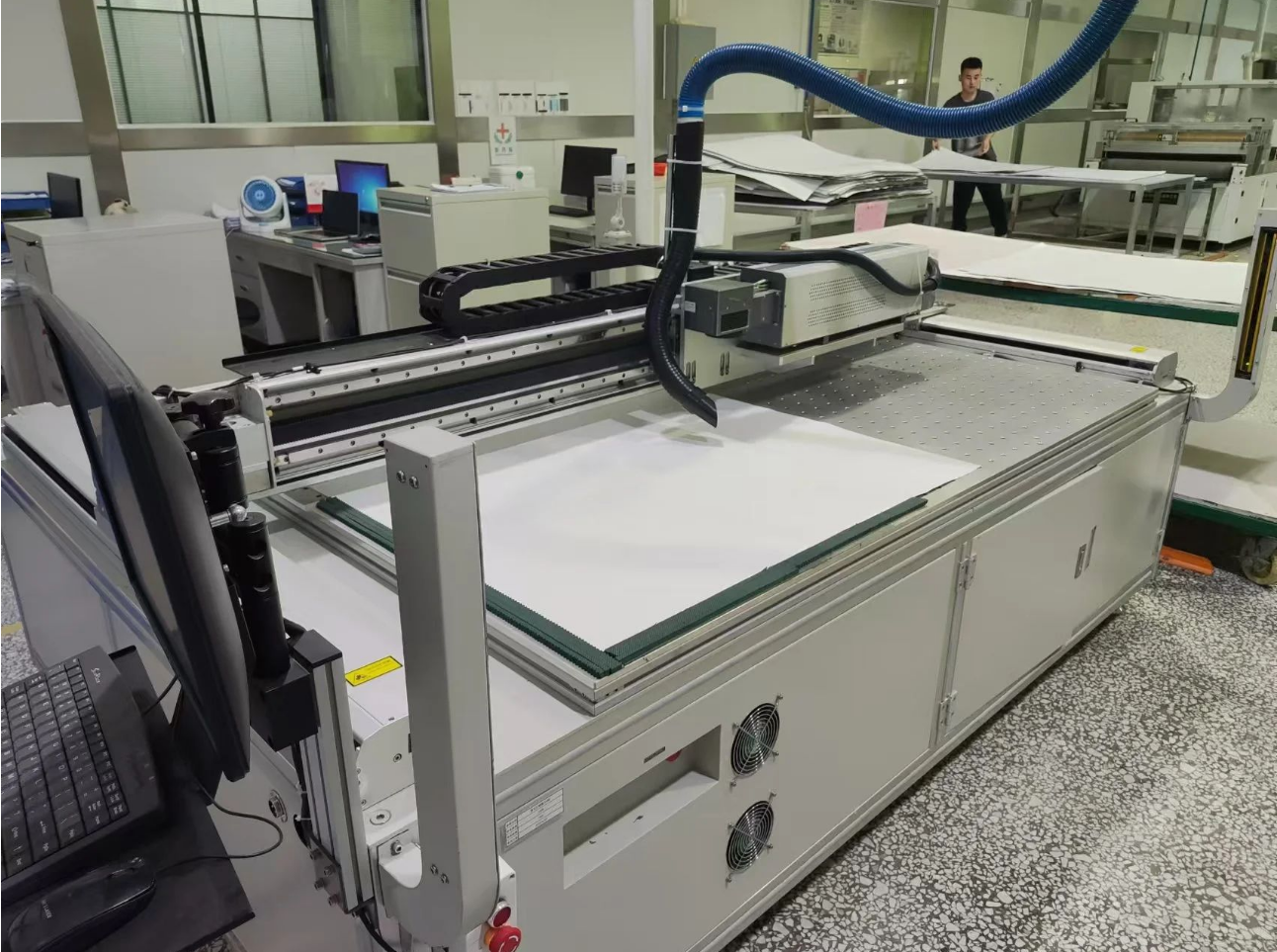

In previous news, we introduced the comprehensive use of A&E CNC yarn cutting (2D plotter) equipment, which has achievedautomation in the cutting of prepreg, thus eliminating the shortcomingsof traditional die stamping equipment such as low accuracy and highlosses, and greatly improving production efficiency.

As an important component of the enterprise's "technology upgrade"strategy, the transformation of 2D cutting technology for prepreg is abreakthrough innovation of A&E's traditional productmanufacturing process.We use computer modeling to personalize theshape and size of prepreg, and then use CNC equipment for high-precision cutting, making the entire prepreg cutting process smooth andefficient.

Application of 2D cutting technology for carbonfiber prepreg

The application of 2D cutting technology has achieved significantresults in the production of A&E carbon fiber bicycleframes.

The carbon fiber prepreg patch cut by CNC yarn cutting (2D plotter)equipment is an important component of handmade carbon fiber framemanufacturing, and workers will stack them according to their numbers.Every carbon fiber bicycle frame produced by A&E is handmade from hundreds of carbon fiber prepreg patches.

In the past, the packaging technology would divide the frame intoseveral parts, package them separately, and then assemble them together by overlapping, which would prolong the working hours. Due tooverlapping assembly, material waste is caused, and the overlappingposition is often poorly designed to fit, resulting in internal wrinkles,multiple breaks, and insufficient strength. Not only does it waste materials, but it also lacks strength and requires patching up, resultingin secondary waste of materials and an increase in the weight of theframe.

After adopting 2D cutting technology,the precision of carbon fiberprepreg patch is high. In addition, we use continuous packagingtechnology in the process, so the carbon fiber patch of the frame canadopt a larger stacking area, which reduces the usage of prepreg patchby 20% compared to traditional cutting methods and reduces productweight.At the same time, this manufacturing process has increasedproduct strength by over 15%.

ln addition, the traditional pre impregnated cutting method requires a lotof manual adjustment and trimming, while the 2D cutting process candirectly output pre impregnated sheets that meet the process requirements through CNC equipment, thereby reducing productiontime and improving production efficiency.

More importantly, due to the precise cutting, the 2D cutting processenables the pre impregnated patch to perfectly fit the shape or specificparts of the frame, making manual operation by workers instantly convenient and efficient.

The carbon fiber frame of A&E not only reduces theuse of materials and weight, but also increases strength, which iscrucial for bicycles that pursue lightweight and high-performance.

The pursuit of technological innovation neverstops

The comprehensive promotion of 2D cutting technology has madeZhongshan Rongnan more precise in material use, greatly reducingmaterial waste.This is beneficial for reducing costs and increasingefficiency in our operations, and also reduces the impact on theenvironment.Against the backdrop of global advocacy for greendevelopment, Zhongshan Rongnan's innovative measures are undoubtedly a positive response to environmental protection concepts.

With the increasing application of new production processes,A&E is actively promoting the continuous advancementof the carbon fiber prepreg industry with its outstanding technology andinnovation capabilities. In the future, we will continue to explore anddevelop more efficient and environmentally friendly productiontechnologies, provide customers with more diverse and high-performance carbon fiber products, and jointly promote the sustainabledevelopment of the industry.

-

Related

information

-

-

Accurate and Efficient | A&E Carbon Fiber PrepregLaser Marking Process Enhances Process Efficiency

As another innovative measure of A&E in the carbon fiber prepreg process, the 2D laser marking process not only reflects the company's advantages in production and technology, but also directly enhances the company's strength.

-

lmproving quality and efficiency | A&E's CNC yarncutting (2D plotter) technology leads a double leap in quality andefficiency

A&E has transformed its pre impregnated cuttingprocess to ensure product quality and significantly reduce productioncosts.

-

Building Defense through Performance | A&E Safety Emergency Drill Successfully Held in the First Half of the Year

A&E held an emergency safety drill for the first half of 2024

-

Quality • Casting the cornerstone|Take you into the Rongsui branch of A&E

About A&E Machinery Industry Co.,Ltd.Rongrui Branch

-