-

Innovation Continues | A&E Bio based Resin CarbonFiber Bicycle Frame Successfully Developed

Release time:2024-08-21 News section:Industry dynamics

-

Innovation never stops, gather strength and forge ahead! Recently,A&E successfully developed a carbon fiber bicycleframe made of bio based epoxy resin prepreg.

The bio based epoxy resin formula used in the development of thecarbon fiber bicycle frame by A&E is made from biobased resins certified by the US Department of Agriculture's USDA BioPreferred SM certification. lt has passed the ISCC international certification and has excellent performance advantages in addition tobeing green and environmentally friendly.

At this point,ZA&E's composite frame will officially enterthe era of bio based technology,and we will continue to be committedto providing global consumers with a more environmentally friendly andhealthier riding experience.At the same time, it also marks an importantstep forward for A&E in the development of carbonfiber prepreg, and is a green innovation for the company's application ofcarbon fiber products.

About bio based epoxy resin

Biobased epoxy resin is one of the hot topics in the field of materialsscience. Its development and application not only help promote thegreen transformation of industrial production, but also provide newideas and solutions for solving global environmental problems.

Biobased epoxy resin refers to epoxy resin prepared using renewablebiological resources such as vegetable oil, starch, cellulose, etc.as rawmaterials.Compared with traditional petroleum based epoxy resins, biobased epoxy resins achieve sustainability in raw material sources, helpreduce dependence on petrochemical fuels, and have significant.

Characteristics of A&E's"Biobased Resin Bicycle Frame"

The carbon fiber bicycle frame made of bio based epoxy resin prepregby A&E is the result of years of dedicated developmentby the company's technical research team. At present, the product hassuccessfully passed a series of frame testing projects, including rigidity,impact, forward tilt, backward tilt, horizontal fatigue,vertical fatigue,pedal fatigue, vibration fatigue and other tests, all of which have obtained excellent test results.Overall, A&E Bio basedEpoxy Resin Carbon Fiber Bicycle Frame has the following significantfeatures and advantages:

1.Excellent lightweight design: The density of bio based epoxy resin islower than that of general epoxy resin, which enables A&E carbon fiber bicycle frame to achieve lightweight whilemaintaining sufficient strength.This lightweight design not onlyenhances the comfort and efficiency of riding, but also makes thebicycle easier to carry and store.

2.Excellent impact resistance: The bio based epoxy resin prepreg hasundergone special processing, and its impact resistance is significantlybetter than that of general epoxy resins. Whether it's daily cycling orhigh-intensity sports competitions, it can be easily handled.

3.Good weather resistance and corrosion resistance: A&E's carbon fiber bicycle frame made of bio based epoxy resinprepreg has good weather resistance and corrosion resistance, and canmaintain stable performance under various climatic conditions,extending its service life.

4.Personalized design: The strong plasticity of bio based epoxy resinprepreg allows our bicycle racks to achieve more personalized designs.Whether it's color, texture, or shape, they can be customized accordingto customers' requirements and preferences, meeting the personalizedneeds of different consumers.

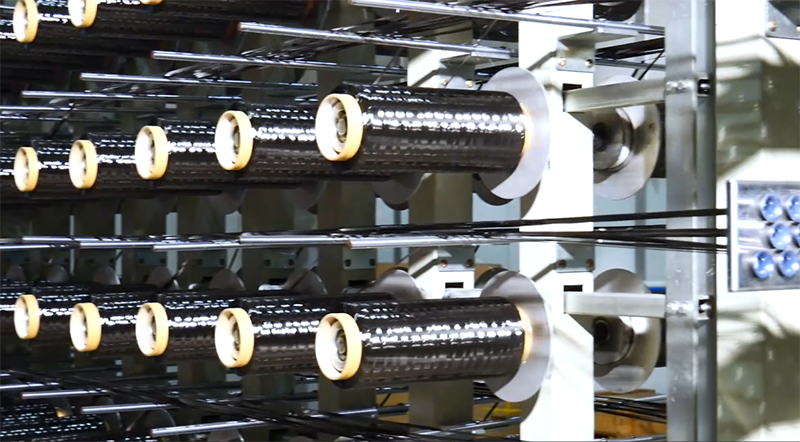

(Biobased epoxy resin modulation workshop)

(Formation of bio based epoxy resin carbonfiber bicycle frame)

(Formation of bio based epoxy resin carbonfiber bicycle frame)

(Biobased Carbon Fiber Bicycle FrameDevelopment and Testing Laboratory)

With the increasing emphasis on sustainable development in variousindustries around the world, the application prospects of bio basedepoxy resins will be even broader.The successful development of the"bio based epoxy resin carbon fiber bicycle frame" indicates thatA&E will make a greater leap in the application of biobased epoxy resin prepreg and its products. In the future,A&E bio based epoxy resin prepreg can not only be used in theproduction of bicycle frames, but also widely applied in various fieldssuch as sports equipment, automotive interiors, building materials, andelectronic products.

At present,A&E has over 80 specifications of carbonfiber prepreg, including bio based epoxy resin prepreg. We are committed to the research and application of carbon fiber compositematerials for a long time, providing professional one-stop solutions forhigh-end composite materials for various industries around the world.

-

Related

information

-

-

Technology A&E | Introduction to Low Temperature Curing Pre impregnated Special Epoxy Resin

A&E‘s low-temperature curing prepreg special epoxyresin can be effectively cured in 60 minutes at 100° C, reducing energyconsumption by more than 30%.

-

Technology A&E | Advantages and Applications of Rapid Hardening Resin

Advantages and Applications of Rapid Hardening Resin

-

Global bestseller | A&E leads the new trend of carbon fiber baseball bat manufacturing

let's explore the production process of carbon fiber baseball bats together.

-

Follow the trend | A&E is fully committed to the transformation of low FAW prepreg technology achievements

A&E is fully committed to the transformation of low FAW prepreg technology achievements

-