-

Technology A&E | Introduction to Low Temperature Curing Pre impregnated Special Epoxy Resin

Release time:2024-08-21 News section:Industry dynamics

-

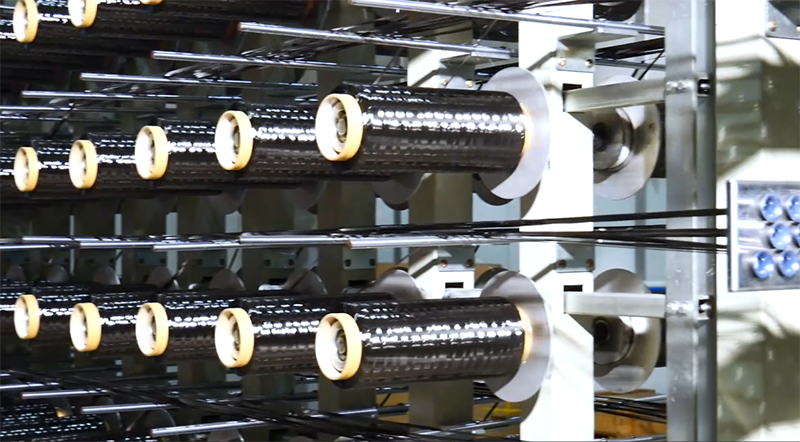

ln the field of composite materials, epoxy resin prepreg is synonymouswith high-performance applications. lt combines reinforcing fibers (suchas carbon fibers) with epoxy resin matrix in advance, and through aspecial process, uniformly coats the resin on the surface of the fibers,and then solidifies under certain temperature and pressure to formcomposite materials with excellent mechanical properties.Especially invarious fields such as aviation, automotive, and wind energy, epoxyresin prepreg provides a lightweight and high-strength solution.However,traditional epoxy resins generally require high-temperaturecuring, which not only consumes a lot of energy but also limits theirapplication in certain sensitive materials.

A&E's Low Temperature Curing Pre impregnated Epoxy Resin

Under the overall trend of the global carbon fiber materials and productsindustry increasingly emphasizing "controlling energy consumption andimproving production efficiency", A&E's "low-temperature curing prepreg special epoxy resin" has emerged.As aunique functional epoxy resin, it has shown wide application potential inmultiple industries due to its low-temperature curing characteristics.

A&E's low-temperature curing prepreg epoxy resin hasmultiple significant advantages:

1、Energy saving and efficient: The product can be effectively cured in 60 minutes at 100 °C. Compared with traditional high-temperaturecuring, this low-temperature curing technology reduces energy consumption by more than 30%, which means significant cost savingsfor large-scale production.

2、 Excellent performance: The product provides composite materials with high strength, high toughness, excellent chemical resistance, and weather resistance. Experimental data shows that the composite material using low-temperature curing prepreg epoxy resin has better tensile strength and bending strength than similar products on the market. At the same time, due to the good flowability and minimal porosity of low-temperature cured prepreg epoxy resin, it reflects extremely high quality and can produce products with higher fiber content.

3、Environmentally friendly: The product meets strict environmentalstandards and helps enterprises achieve green production. In addition,the product has a shelf life of about three weeks at 25 °℃, making production more effortless.

Application of A&E's LowTemperature Curing Pre impregnated Epoxy Resin

1、Aerospace: Used for manufacturing lightweight, high-strengthaircraft components to improve fuel efficiency.

2、Automotive manufacturing: improving the performance and durability of automotive components while reducing the overall weight ofthe vehicle.

3、Wind power generation: used to manufacture blades for windturbines, improving power generation efficiency and blade life.

4、Sports equipment such as golf clubs and bicycle frames providebetter performance and comfort.

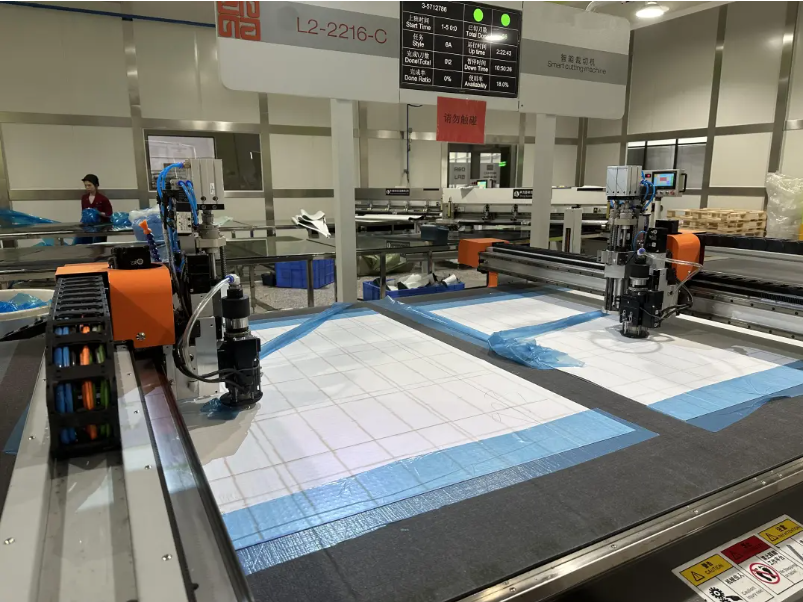

A&E's low-temperature curing prepreg special epoxyresin not only solves the energy consumption problem of traditionalepoxy resin in the curing process, but also provides more efficient andenvironmentally friendly material choices for various industries.At present,A&E undertakes the intelligent manufacturing and processing of various specifications of carbon fiberprepreg and products worldwide,such as carbon fiber baseball bats,fishing rods, golf clubs and other sports and leisure products; 3C digitalproducts; New unmanned aerial vehicle products; Medical imagingdiagnostic equipment and supplies; Large scale industrial.

-

Related

information

-

-

Innovation Continues | A&E Bio based Resin CarbonFiber Bicycle Frame Successfully Developed

A&E has officially entered theera of bio based composite frames.

-

Technology A&E | Advantages and Applications of Rapid Hardening Resin

Advantages and Applications of Rapid Hardening Resin

-

Global bestseller | A&E leads the new trend of carbon fiber baseball bat manufacturing

let's explore the production process of carbon fiber baseball bats together.

-

Follow the trend | A&E is fully committed to the transformation of low FAW prepreg technology achievements

A&E is fully committed to the transformation of low FAW prepreg technology achievements

-